Internship Overview

ATC at NIWC Atlantic spans multiple components—AFLCS (Airfield Lighting Control Systems), ETVS (Enhanced Terminal Voice Switch), EPROM chips, radios, METOC, Polar Program, and special projects. This summer I focused on three core streams: AFLCS lightboard restoration, ETVS + EPROM workflow, and radio tuning & documentation.

Duration & Award

NREIP is typically a 10-week internship. With lab approval, I extended to a 12-week appointment to complete and document additional ATC work.

I was also selected for the South Carolina Internship Program (SCIP) award—a University of South Carolina initiative that provides financial supplements for in-state internships in high-demand industries. It helps offset internship costs while contributing to South Carolina’s workforce.

ATC Components I Worked With

- AFLCS

- ETVS

- EPROM Chips

- Radios

- METOC

- Polar Program

- Special Projects

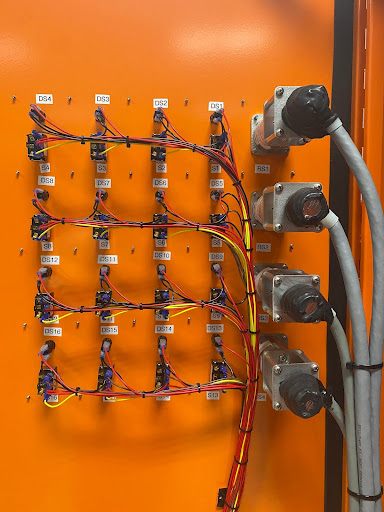

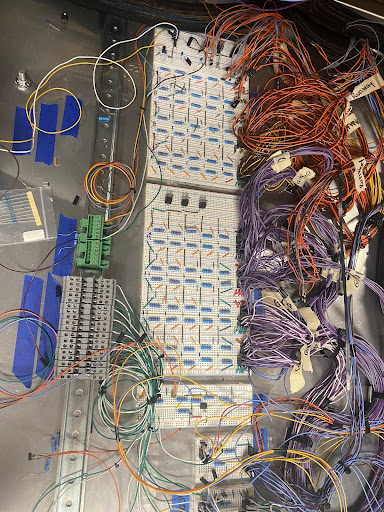

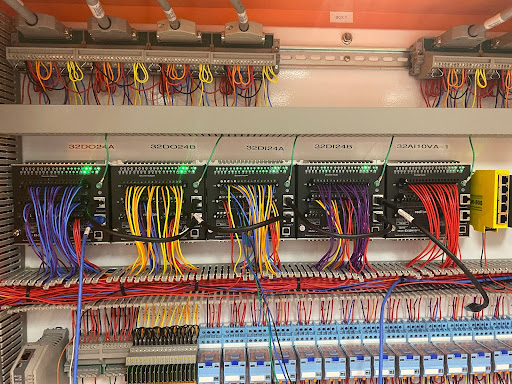

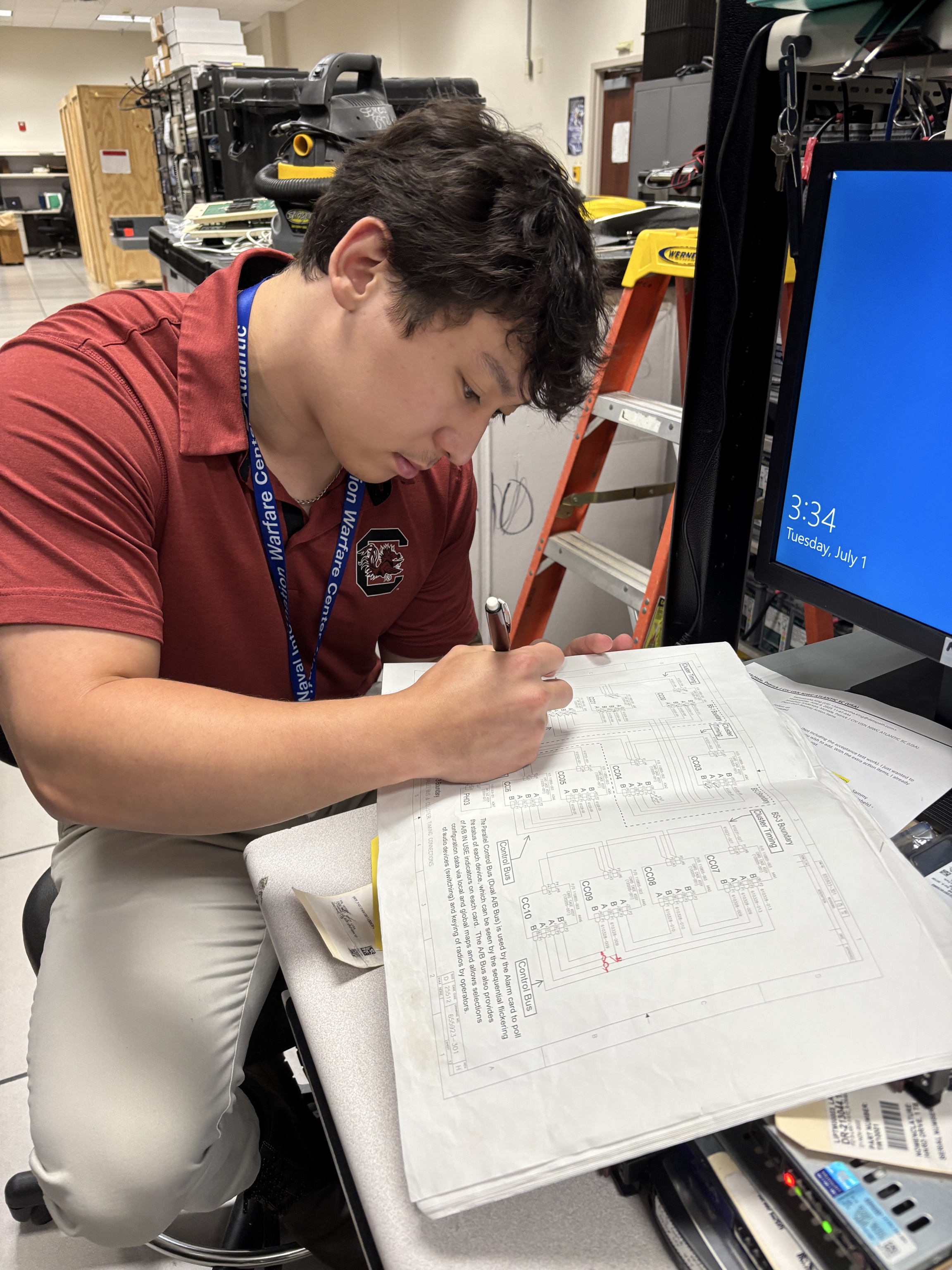

AFLCS — Airfield Lighting Control System

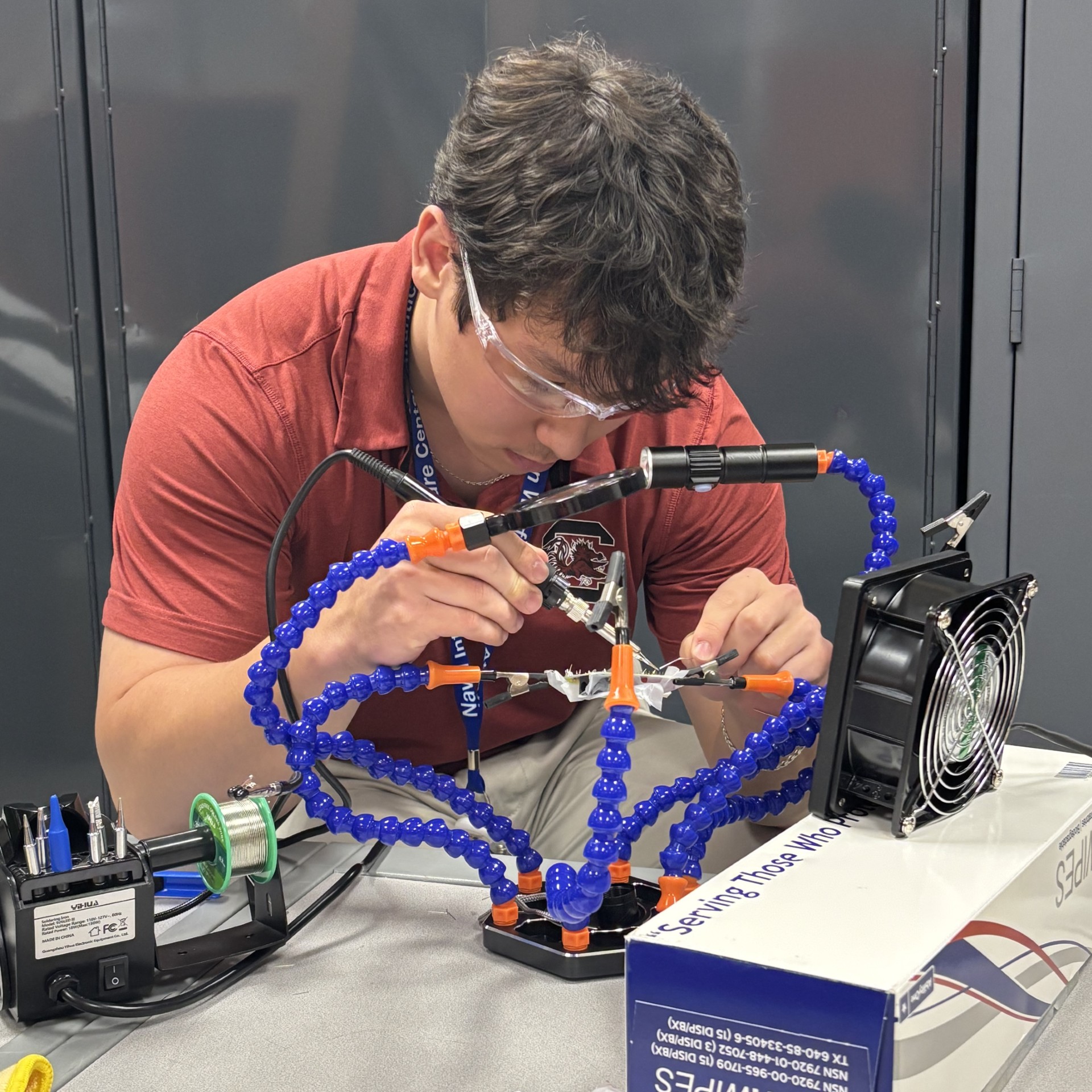

AFLCS manages runway/taxiway lighting states for safe aircraft movement. My main tasking was the lightboard: planning and executing a method to solder and secure all connections, then verifying behavior against expected states.

- Devised a wire-soldering and board-securement plan.

- Traced and labeled color-coded wiring; drew schematics.

- Validated transitions and fault handling with multimeter checks.

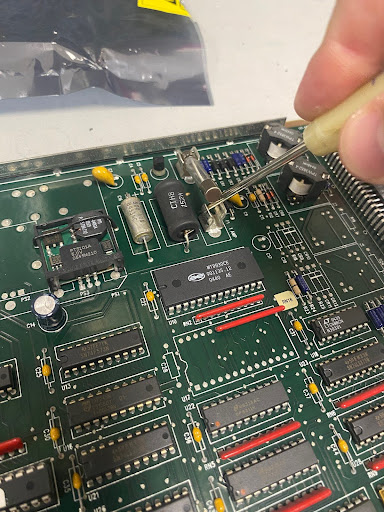

ETVS — EPROM Workflow

ETVS is the voice communications switching system used in ATC facilities. I executed the full EPROM workflow and board integration from prep to packaged delivery.

-

1

Prep & Remove Labels

Clear legacy stickers, confirm part IDs, and prep chips for erase/program cycles.

-

2

Erase (“Cook”)

UV erasure to a clean state; spot-check with reads before writing.

-

3

Program & Verify

Write firmware, verify checksums/reads, and log versions for traceability.

-

4

Relabel & Install

Accurately relabel and seat chips in the correct sockets on the ETVS board.

-

5

Package & Document

Final packaging with documentation so the next engineer can ramp Day 1.

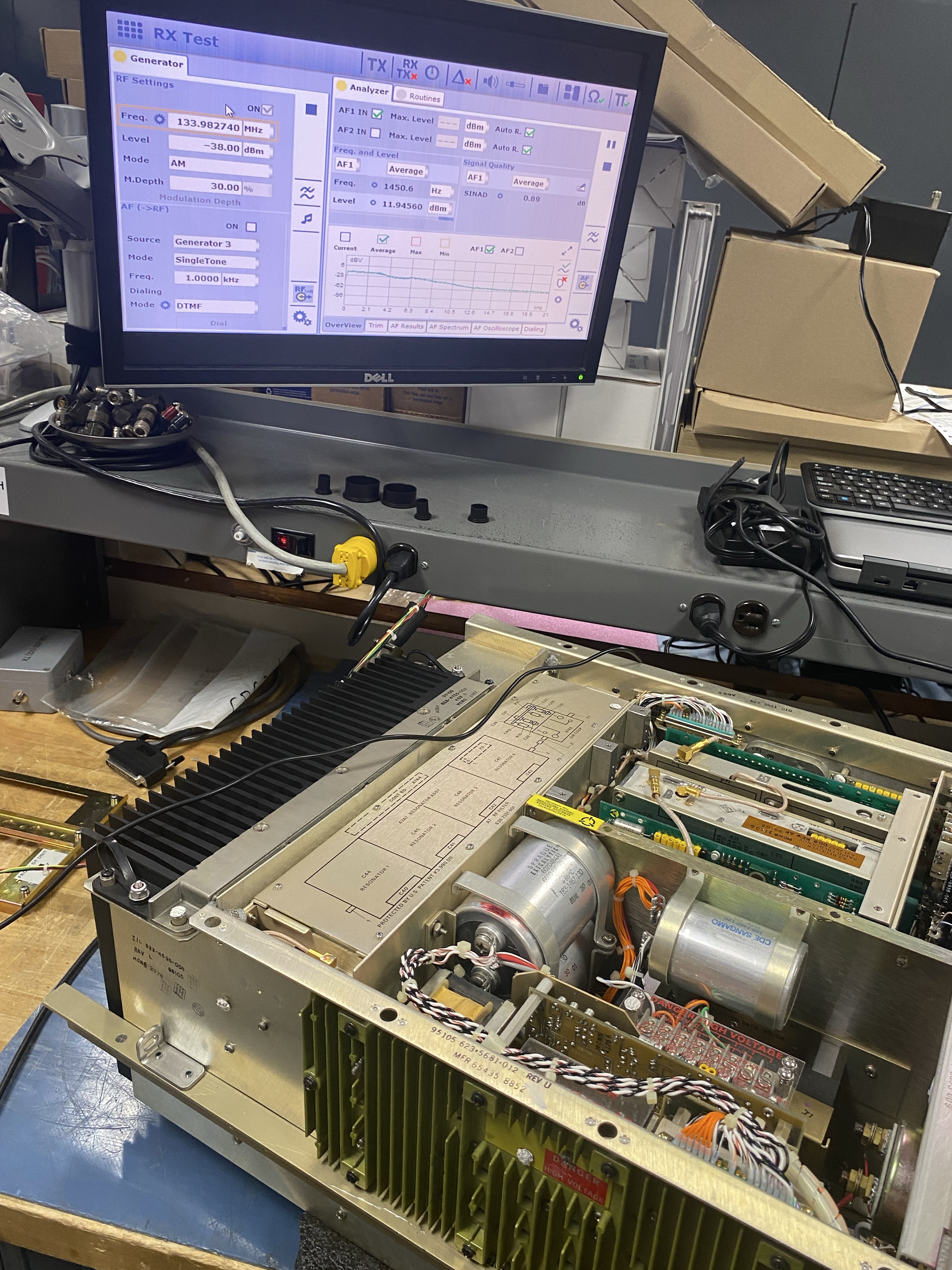

Radios — Tuning & Documentation

We tuned and documented 20+ radios using a test set to verify alignment and performance. Equipment covered:

- CM300/350 — Transmitters & Receivers

- CM200 — Receivers

- Transceivers

Procedure included alignment, recording config values, and follow-up tasks for any drift.

Takeaways & Gratitude

- End-to-end hardware workflow: planning, soldering, labeling, verification.

- ETVS + EPROM process: erase, program, validate, relabel, install, document.

- Radio alignment: procedure discipline, measurement, and traceable records.

- Documentation-first mindset so the next engineer can ramp Day 1.

- Deepened systems view of ATC (AFLCS, ETVS, radios, METOC, ops).

Image Library

A few extra shots from the internship. Click any thumbnail to view full size.